In professional loudspeaker design, precision is essential. Critical parameters such as frequency response, distortion, and directivity must be measured under ideal conditions to ensure the system’s acoustic performance aligns precisely with its physical design. This requires a controlled, interference-free environment, making the anechoic chamber an indispensable tool in advanced acoustic R&D.

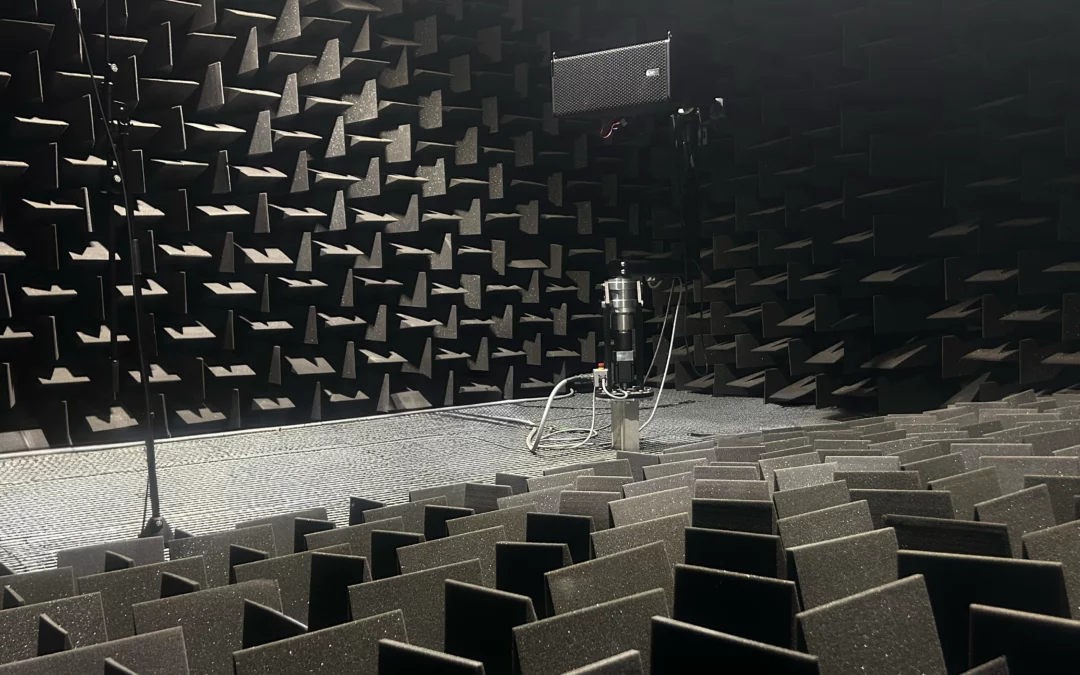

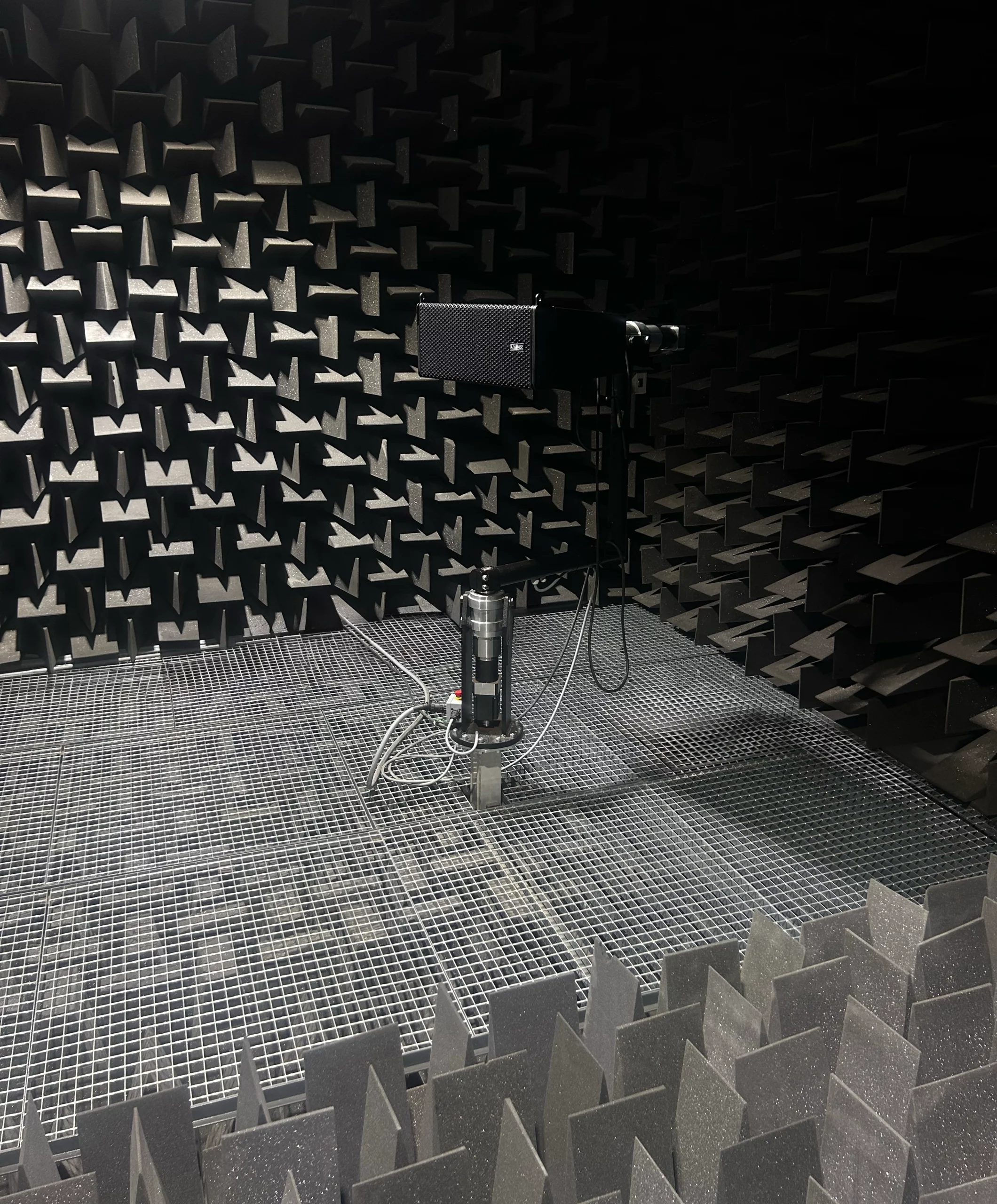

At Lynx Pro Audio, our anechoic chamber plays a vital role in the development of all sound systems, from initial prototypes to final products. By simulating a reflection-free space, it reveals the loudspeaker’s true acoustic behavior, free from the artifacts introduced by typical room acoustics.

This setup allows us to meticulously analyze key acoustic parameters, including frequency response, sensitivity, on-axis and off-axis behavior, horizontal and vertical dispersion, and overall system efficiency at realistic sound pressure levels. Such data is critical for optimizing both the physical loudspeaker design and its associated digital signal processing (DSP), ensuring each system delivers consistent and predictable performance.

Our in-house anechoic chamber supports accurate free-field measurements starting from 100 Hz, comfortably covering the most relevant frequency range for Lynx Pro Audio systems.

A cornerstone of this facility is our automated robotic measurement system, a computer-controlled 3D arm capable of rotating the loudspeaker across multiple axes. This precision motion enables full 360° polar data acquisition, commonly known as balloon measurements, which are essential for visualizing each model’s acoustic dispersion.

The measurement microphone is positioned with high accuracy using a guided mechanical system, ensuring precise and repeatable placement at every angle. This level of control is crucial for achieving consistent, reproducible measurements across multiple prototypes or test sessions.

All measurement data is seamlessly integrated into our proprietary Rainbow 3D electroacoustic prediction software. By incorporating real-world data from the anechoic chamber, Rainbow 3D can simulate loudspeaker performance in actual venues whether theaters, multipurpose halls, or open outdoor spaces. This alignment between measured and predicted performance provides installers and engineers with the confidence and reliability they need throughout the entire project lifecycle, from system design to final installation.

Having our own anechoic chamber significantly accelerates product development while reducing reliance on external laboratories. This agility enhances everything from validating new designs and calibrating DSP presets to comparing different system configurations. It is particularly beneficial for outdoor applications like line array systems, where control, predictability, and coverage consistency are critical.

Ultimately, this in-house measurement capability ensures that the technical specifications we publish, accurately reflect each loudspeaker’s real-world performance under standardized conditions.